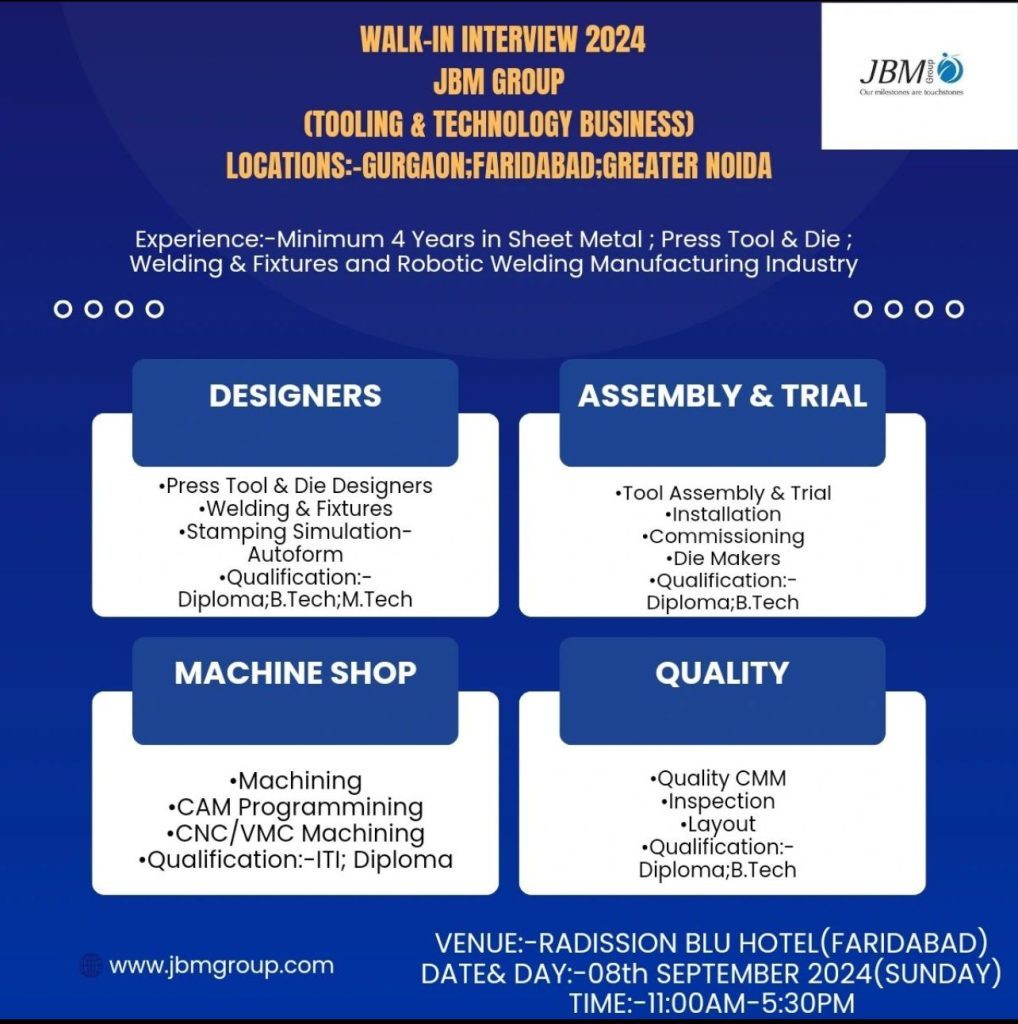

WALK-IN INTERVIEW Drive for the Tooling & Technology Business by JBM Group

Introduction The manufacturing industry is constantly evolving, and with technological advancements, there is a growing demand for skilled professionals in the tooling and technology sectors. JBM Group, a renowned leader in manufacturing, engineering, and technology, is conducting a Walk-In Interview Drive for their Tooling & Technology Business. This drive presents an excellent opportunity for candidates with expertise in sheet metal, press tool & die, welding fixtures, and robotic welding manufacturing. With multiple positions open in Gurgaon, Faridabad, and Greater Noida, this drive is the perfect gateway to a fulfilling career with JBM Group. Let’s dive into the details of the job positions, the hiring process, and tips on how to ace the interview.About JBM Group

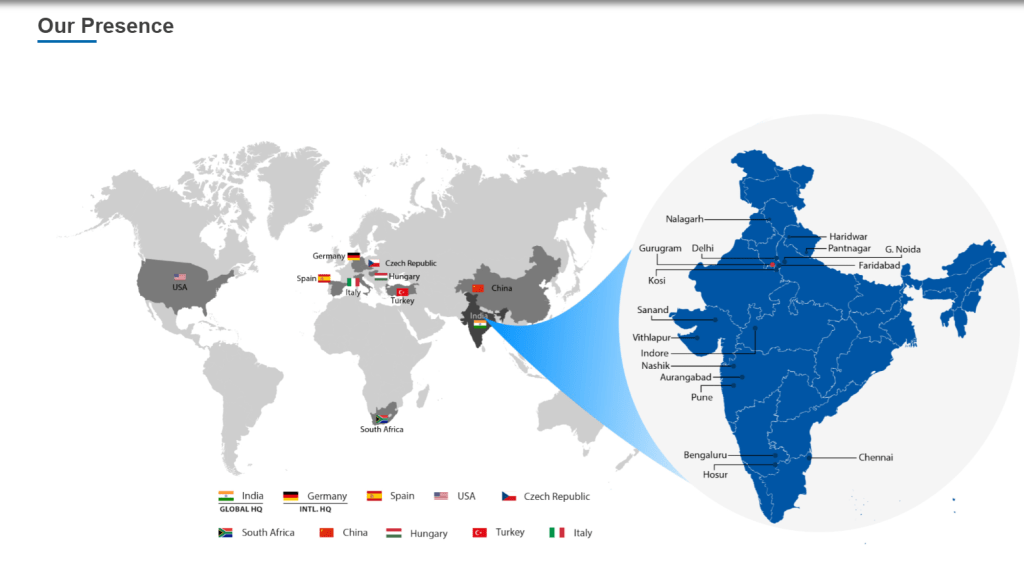

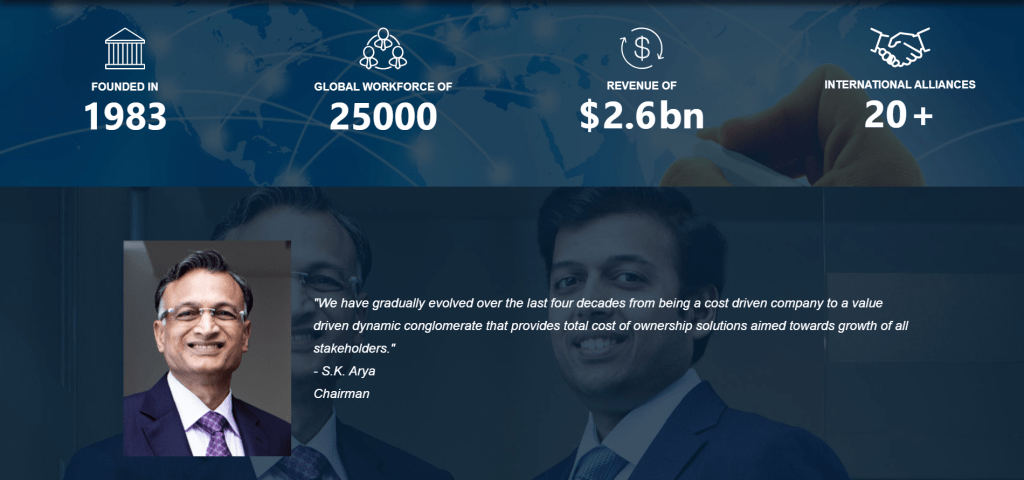

JBM Group, established in 1983, is one of India’s leading business conglomerates with diversified interests across multiple industries, including automotive, engineering, renewable energy, and education. With over four decades of experience, the company has a global footprint with operations in more than 25 locations worldwide. JBM Group is recognized for its innovation, quality, and commitment to excellence, making it a preferred employer for professionals looking to build a rewarding career. The Tooling & Technology Business unit of JBM Group focuses on advanced manufacturing solutions, specializing in sheet metal, press tool & die, welding fixtures, and robotic welding manufacturing. The unit serves various industries, including automotive, heavy engineering, and industrial automation, offering high-precision tools and state-of-the-art technology solutions.Job Positions Available

JBM Group is looking to fill several key positions within their Tooling & Technology Business. Below are the details of the job roles available:1. Designers

- Specializations:

- Press Tool & Die Designers

- Welding & Fixtures

- Stamping Simulation – Autoform

- Qualifications: Diploma, B.Tech, M.Tech

- Experience: Minimum 4 years in sheet metal design, press tool & die, and welding fixtures.

- Job Description:

- Design and develop press tools and dies using CAD software.

- Create welding and fixture designs for various projects.

- Work on stamping simulations using Autoform to optimize designs for manufacturing.

- Collaborate with engineering and production teams to ensure seamless integration of designs into production processes.

2. Assembly & Trial

- Specializations:

- Tool Assembly & Trial

- Installation

- Commissioning

- Die Makers

- Qualifications: Diploma, B.Tech

- Experience: Minimum 4 years in tool assembly, installation, and commissioning.

- Job Description:

- Assemble and trial tools and dies for manufacturing.

- Install and commission equipment at client sites.

- Ensure that tools are correctly set up and functioning as required.

- Collaborate with the quality and production teams to resolve any issues during the trial phase.

Join Our Group To Get More Job Alerts -Click Here

3. Machine Shop

- Specializations:

- Machining

- CAM Programming

- CNC/VMC Machining

- Qualifications: ITI, Diploma

- Experience: Minimum 4 years in machining, CAM programming, and CNC/VMC operations.

- Job Description:

- Operate and program CNC and VMC machines for precision machining tasks.

- Use CAM software to create programs for machining.

- Perform regular maintenance and troubleshooting of machines.

- Work closely with the design and production teams to ensure that machined parts meet design specifications.

4. Quality

- Specializations:

- Quality CMM

- Inspection

- Layout

- Qualifications: Diploma, B.Tech

- Experience: Minimum 4 years in quality control, inspection, and CMM operations.

- Job Description:

- Perform quality inspections using CMM machines and other precision tools.

- Ensure that all manufactured components meet design specifications and quality standards.

- Create inspection reports and maintain documentation for quality audits.

- Collaborate with the production and design teams to resolve quality issues.

Join Our Group To Get More Job Alerts -Click Here

Hiring Process at JBM Group

The hiring process for JBM Group is designed to be efficient and thorough, ensuring that only the most qualified candidates are selected. Here’s what you can expect:Step 1: Walk-In Interview

- Interested candidates are invited to the walk-in interview at the Radisson Blu Hotel, Faridabad, on 8th September 2024 (Sunday) from 11:00 AM to 5:30 PM.

- Ensure that you bring multiple copies of your updated resume, academic certificates, work experience certificates, and identification proof.

Step 2: Technical Evaluation

- After the initial interview, shortlisted candidates will undergo a technical evaluation based on their respective specializations.

- This may include a practical test, written exam, or an assessment of your previous work.

Step 3: HR Interview

- Candidates who successfully clear the technical evaluation will have a one-on-one interview with the HR team.

- The HR interview will assess your cultural fit, communication skills, and willingness to align with JBM Group’s core values.

Step 4: Offer Letter

- Successful candidates will receive an offer letter with details about the role, compensation, and onboarding process.

- You will be required to complete any pre-employment formalities, such as medical checkups and background verification, before joining.

Join Our Group To Get More Job Alerts -Click Here

Top 10 Interview Questions and Answers

To help you prepare for the interview, here are the top 10 questions that you may encounter during the hiring process at JBM Group, along with sample answers.1. Tell us about your experience in the tooling and technology industry.

- Answer: “I have over 4 years of experience in the tooling and technology industry, specializing in sheet metal design, press tool & die, and welding fixtures. I have worked on several projects where I was responsible for designing tools, ensuring quality control, and collaborating with the production team to optimize manufacturing processes.”

2. What challenges have you faced in tool design, and how did you overcome them?

- Answer: “One of the main challenges I faced was ensuring that the tool designs met the required tolerances while also being cost-effective. To overcome this, I collaborated closely with the production team to understand the limitations of the machinery and made adjustments to the designs to achieve the best possible outcome.”

3. How do you ensure quality in your work?

- Answer: “I prioritize quality by adhering to strict quality control processes and using precision tools for inspections. I also maintain clear communication with the production and design teams to address any issues promptly and make necessary adjustments.”

4. What software tools are you proficient in?

- Answer: “I am proficient in AutoCAD, SolidWorks, CATIA, and Autoform for tool and die design. Additionally, I have experience using CAM software for machining and programming CNC/VMC machines.”

5. Describe a project where you successfully improved the production process.

- Answer: “In my previous role, I worked on a project where we were facing delays due to inefficient tooling design. I identified the bottleneck, redesigned the tool to reduce setup time, and collaborated with the production team to implement the changes. As a result, we were able to reduce production time by 15%.”

6. How do you handle tight deadlines in a manufacturing environment?

- Answer: “I handle tight deadlines by prioritizing tasks based on their impact on the overall project. I also ensure that I communicate effectively with the team, delegate tasks when necessary, and stay focused on the end goal to meet deadlines without compromising on quality.”

7. Can you explain the importance of stamping simulation in tool design?

- Answer: “Stamping simulation, like Autoform, is crucial in tool design because it allows us to predict and optimize the stamping process before manufacturing. By simulating the process, we can identify potential issues, reduce material waste, and ensure that the final product meets the required specifications.”

8. How do you stay updated with the latest trends and technologies in the industry?

- Answer: “I regularly attend industry conferences, participate in online forums, and subscribe to industry publications to stay updated with the latest trends. I also take online courses and certifications to enhance my skills and keep up with technological advancements.”

9. Why do you want to work at JBM Group?

- Answer: “JBM Group is a leader in the manufacturing industry, known for its innovation and commitment to excellence. I am excited about the opportunity to work with a company that is at the forefront of technology and to contribute to its continued success through my expertise in tooling and technology.”

10. How do you ensure safety in the workplace?

- Answer: “Safety is a top priority for me. I ensure that all safety protocols are followed during the design, assembly, and production phases. I also conduct regular safety audits and training sessions to keep the team informed about best practices and to minimize the risk of accidents.”

Conclusion

The Walk-In Interview Drive by JBM Group is a fantastic opportunity for professionals with experience in sheet metal, press tool & die, welding fixtures, and robotic welding manufacturing to take their careers to the next level. With a strong focus on innovation, quality, and precision, JBM Group offers a dynamic and challenging work environment where you can thrive and grow. If you meet the qualifications and are ready to make a significant impact, don’t miss this chance to join one of the industry’s most respected companies. Prepare well, bring your best to the interview

I am interested in tool installation and design.