Latest Career Opportunities at Jindal Steel Ltd-2025

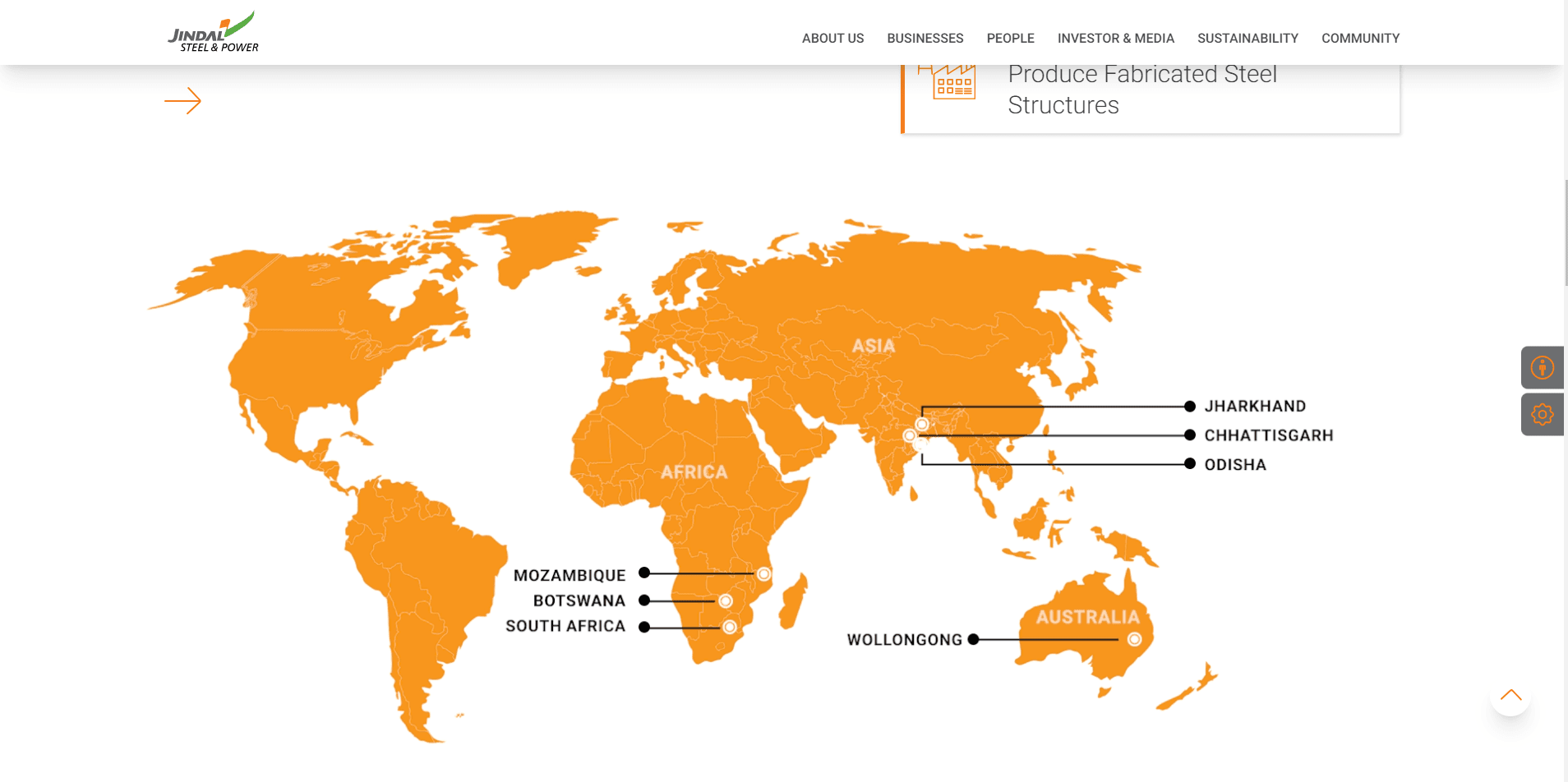

Are you looking for the latest career opportunities at Jindal Steel Ltd-2025? Jindal Steel Ltd, a renowned name in the steel and energy industry, offers a range of exciting roles across its various locations in India. With cutting-edge facilities and a commitment to innovation, Jindal Steel is the place to build a thriving career.

Why Choose Jindal Steel Ltd?

Jindal Steel Ltd is a pioneer in the steel industry, with a legacy of delivering excellence for decades. It is known for its modern plants, sustainable practices, and a robust workforce. Working at Jindal Steel means being part of a dynamic team committed to creating a sustainable future.

Latest Career Opportunities at Jindal Steel Ltd-2025

Below are the latest openings at Jindal Steel Ltd for 2025. Each position is designed to offer challenging roles that help employees grow professionally.

1. Engineer

📍 Jajpur, Odisha, India

🕒 Experience: 0 – 5 Years

Qualification & Skills

-

B.E./B.Tech in Mechanical Engineering

-

Strong understanding of mechanical systems and maintenance in pellet plants

-

Experience in preventive maintenance, troubleshooting, and failure analysis

-

Good communication and coordination skills

-

Knowledge of safety standards and operational efficiency improvement

Key Responsibilities

-

Oversee the maintenance and smooth operation of mechanical equipment in the Chrome Pellet Plant

-

Plan and implement preventive and corrective maintenance schedules

-

Analyze equipment failure and take corrective actions to avoid recurrence

-

Ensure compliance with safety and quality standards

-

Coordinate with other departments to ensure minimal downtime and enhanced productivity

-

Maintain proper documentation and reports for audits and reviews

Apply Now

Join Our WhatsApp Group To Get Premium Job Alerts-Click Here

2. Executive-System Audit

Location: Hisar ,haryana

Experience: 0 – 4 Years

Key Responsibilities:

Invoice Verification: Review invoices for raw materials, services, projects, logistics, and MRO, ensuring accuracy and compliance with purchase orders, contracts, and approvals.

• Compliance Checks: Verify GST, TDS, and tax compliance, ensuring all necessary documentation is in place before payments.

• Discrepancy Resolution: Identify and resolve discrepancies in invoices by collaborating with procurement, finance, and logistics teams.

• Reporting: Prepare reports on pre-audit findings, highlighting discrepancies and suggesting improvements.

• Process Improvement: Continuously improve pre-audit processes for efficiency and compliance.

• Education: Bachelor’s degree in Accounting, Finance, or related field (CA Inter, CMA Inter preferred).

• Experience: 0-4 years in Accounts Payable or pre-audit functions, with experience in raw materials, services, and logistics.

• Skills: Strong knowledge of AP processes, GST/TDS regulations, attention to detail, and proficiency in Microsoft Office and accounting software (SAP preferred).

Apply Now

3. Junior Engineer (Power Plant)

Location: Jajpur, Odisha, India

Experience Required: 3 – 5 Years

Department: Power Plant

Key Responsibilities:

-

Operate and monitor power plant systems and equipment in compliance with Standard Operating Procedures (SOPs).

-

Conduct routine checks and inspections of turbines, boilers, generators, and auxiliary systems.

-

Assist in planning and execution of shift activities and operational tasks.

-

Perform basic troubleshooting and first-level maintenance.

-

Monitor critical process parameters and take timely corrective actions.

-

Prepare and maintain daily operation and power generation reports.

-

Coordinate with maintenance and electrical teams for scheduled and emergency maintenance.

-

Ensure adherence to safety, health, and environmental standards and regulations.

Technical Skills & Competencies:

-

Experience in operating captive/industrial power plants (coal-based, gas turbine, or WHRB preferred).

-

Proficient in DCS (Distributed Control System) operations and plant instrumentation.

-

Knowledge of high-capacity steam turbines and boiler operations.

-

Understanding of load management, fuel handling, and efficiency optimization.

-

Familiarity with SAP or equivalent ERP software for plant operations and material management.

-

Strong problem-solving and analytical skills.

Educational Qualification:

-

Diploma or B.E./B.Tech in Mechanical, Electrical, or Power Engineering from a recognized institution.

Apply Now

Join Our WhatsApp Group To Get Premium Job Alerts-Click Here

4. Associate – Regional Sales

Location: Hisar, Haryana, India

Department: Sales & Marketing

Experience:5 – 7 Years

Key Responsibilities:

To appoint dealers and Sub dealers in assigned

- To increase Market and expand customer base

- To meet dealer, distributor, sub dealers and generate sales

- To meet sanitary ware product and get approved in projects

- To achieve sales targets set by department HODs

- Ensure to work towards monthly or annual targets

- Take part in promotions activities

- Team Management and team development

SkillsandQualifications

- 2-5yearsofworkexperienceinsalesdepartment

- Anactivelistener tounderstandthedetailsfromvariousstakeholders

- Self-motivated and driven by targets

- Excellentinterpersonalandcommunicationskills

Apply Now

5. Assistant Engineer (HSM)

Location: Jajpur, Odisha, India

Experience: 4 – 5 Years

Key Responsibilities:

Design and Detailing:

-

Prepare detailed fabrication drawings, including but not limited to assembly drawings, part drawings, and connection details for Hot Strip Mill components and structures.

-

Interpret mechanical and structural design specifications, calculations, and layouts to develop accurate fabrication and installation drawings.

-

Develop 3D models and detailed drawings using CAD software such as AutoCAD, SolidWorks, or similar.

-

Ensure designs meet industry standards, safety regulations, and operational efficiency.

Project and Maintenance Support:

-

Assist senior engineers in planning and execution of Hot Strip Mill projects, upgrades, and process optimizations.

-

Support in root cause analysis of equipment issues and implement preventive maintenance solutions.

-

Prepare technical documentation including reports, specifications, and project updates.

Fabrication and Erection Coordination:

-

Coordinate with fabrication vendors and erection teams to ensure drawings are implemented accurately on-site.

-

Resolve design and assembly issues during fabrication or installation stages.

-

Ensure all fabrication works are optimized for efficiency, safety, and cost-effectiveness.

Required Skills and Qualifications:

Educational Qualification:

-

Bachelor’s degree in Mechanical Engineering or a related field.

Experience:

-

4 to 5 years of experience in Hot Strip Mill or steel plant operations with a strong background in mechanical design and detailing.

-

Familiarity with fabrication and erection processes in industrial projects.

-

Proficiency in CAD tools and mechanical drawing standards.

-

Hands-on experience working with vendors, contractors, and multidisciplinary engineering teams.

Apply Now

6. JR. ENGINEER-Pickling

Location: Ghaziabad, Uttar Pradesh, India

Department:Pickling

Experience:2 – 4 Years

Key Responsibilities:

- Design maintenance procedures and strategies for the plant or machinery on which you are working

- Identify faults and efficiency issues

- Respond to equipment breakdowns, provide first line diagnostic and arrange repairs or replacements

- Perform quality inspections to ensure compliance with health and safety regulations

- Complete electronic notification or paper documents to keep track of tasks

- Monitor budgets and costs for maintenance

Apply Now

7. Executive Engineer (HSM)

Location: Jajpur, Odisha, India

Experience: 6 – 8 Years

Key Responsibilities:

Operations & Maintenance:

-

Lead and supervise the daily operations and maintenance activities of the Hot Strip Mill (HSM) section.

-

Monitor production performance, equipment efficiency, and process parameters to ensure optimal operation.

-

Troubleshoot equipment issues and lead root cause analysis for recurring mechanical and process faults.

-

Drive preventive and predictive maintenance strategies to minimize downtime and improve plant reliability.

Project Execution & Engineering Support:

-

Manage technical aspects of capital and maintenance projects within the HSM unit.

-

Review and approve engineering drawings, material specifications, and technical documents.

-

Coordinate with internal teams and external vendors for timely execution of projects.

-

Ensure compliance with safety, quality, and statutory requirements.

Team Leadership & Development:

-

Guide and mentor junior engineers and technical staff.

-

Promote a culture of continuous improvement and operational excellence within the team.

-

Conduct training programs for skill enhancement and safety awareness.

Required Skills and Qualifications:

Educational Qualification:

-

Bachelor’s degree in Mechanical Engineering or a related discipline.

Experience:

-

6 to 8 years of hands-on experience in Hot Strip Mill operations, maintenance, and project execution.

-

Strong understanding of rolling mill equipment, process flow, and automation systems.

-

Proficient in interpreting engineering drawings, technical standards, and root cause methodologies.

-

Effective communication, leadership, and team management skills.

Apply Now

Join Our WhatsApp Group To Get Premium Job Alerts-Click Here

8. Executive-Maintenance

Location: Mumbai, Maharashtra, India

Department: Maintenance

Experience: 4-7 years

Key Responsibilities:

-

Mechanical Maintenance:

-

Perform routine and preventive maintenance on mechanical equipment, including but not limited to CNC machines, rolling mills, press machines, welding machines, conveyors, and other machinery used in the stainless steel fabrication process.

-

Ensure timely inspections and calibration of mechanical equipment to minimize downtime and ensure high-quality production standards.

-

-

Equipment Troubleshooting & Repairs:

-

Diagnose mechanical faults and failures in production machinery and equipment, quickly identifying the root cause of issues.

-

Perform corrective maintenance and repairs, including replacing or repairing components such as motors, pumps, bearings, gears, compressors, and hydraulic systems.

-

Ensure all repairs are performed in line with safety and quality standards.

-

-

Preventive & Predictive Maintenance:

-

Implement and follow a scheduled preventive maintenance program to ensure all equipment operates at optimal efficiency.

-

Monitor mechanical systems and machinery to predict potential issues, ensuring that necessary repairs are done before breakdowns occur.

-

Maintain and review maintenance logs, ensuring that all activities are documented for future reference and audits.

-

-

Educational Qualifications:

-

Bachelor’s degree or diploma in Mechanical Engineering, Industrial Engineering, or a related technical field.

-

-

Experience:

-

Minimum 4-7 years of hands-on experience in maintenance of mechanical systems, preferably in a stainless steel fabrication or manufacturing plant.

-

Experience with fabrication machinery, welding equipment, CNC machines, and automated production systems is highly desirable.

-

Apply Now

9. JD – Associate Manager (Purchase)

Location: Mumbai, Maharashtra, India

Experience: 5 – 9 Years

Key Responsibilities:

Key Responsibilities:

- Procurement Management:

- Oversee the procurement of raw materials (e.g., iron ore, coal, scrap steel) and other consumables used in steel manufacturing.

- Manage vendor selection and evaluation, ensuring cost-effective and timely delivery of materials.

- Negotiate contracts with suppliers for competitive pricing and favorable terms.

- Maintain an effective inventory management system to ensure availability of materials while minimizing excess stock.

- Supplier Relationship Management:

- Establish and maintain positive relationships with key suppliers and vendors.

- Monitor supplier performance regularly and resolve any issues related to quality, delivery, and price.

- Conduct periodic reviews of supplier capabilities and make recommendations for improving vendor base.

- Cost Control & Budgeting:

- Develop and manage procurement budgets, ensuring cost targets are met.

- Implement strategies to control material costs and reduce wastage.

- Prepare reports on procurement activities, including cost analysis and savings.

Qualifications:

- Education:

- Bachelor’s degree in Engineering, Supply Chain Management, Business Administration, or a related field.

- Post-graduate degree or relevant certification (e.g., MBA, CIPS) will be an advantage.

- Experience:

- Minimum 6-9 years of experience in procurement, purchasing, or supply chain management, preferably in the steel or manufacturing industry.

- Strong knowledge of steel production materials and suppliers is highly desirable.

Apply Now

10. Assistant Engineer (CRM)

Location: Jajpur, Odisha, India

Experience: 3 – 6 Years

Key Responsibilities:

Process Support and Optimization:

-

Assist in the day-to-day operations and maintenance of the Cold Rolling Mill (CRM) to ensure smooth production.

-

Monitor and optimize process parameters to improve product quality, yield, and operational efficiency.

-

Work closely with senior engineers to troubleshoot and resolve any process-related issues.

Engineering and Technical Support:

-

Prepare and review technical documents, reports, and drawings related to the Cold Rolling Mill processes.

-

Collaborate with the maintenance team to ensure timely corrective and preventive maintenance actions.

-

Analyze process data and recommend process improvements to increase throughput and reduce defects.

Project Assistance:

-

Support in project execution, including installation, testing, and commissioning of new equipment in the CRM section.

-

Assist in the preparation of project reports and ensure compliance with technical specifications and timelines.

Required Skills and Qualifications:

Educational Qualification:

-

Bachelor’s degree in Mechanical, Production, or Metallurgical Engineering.

Experience:

-

3 to 6 years of experience in Cold Rolling Mill operations or a similar manufacturing environment.

-

Strong understanding of cold rolling processes, equipment, and related technologies.

-

Proficiency in analyzing process data and applying troubleshooting techniques.

Apply Now

Join Our WhatsApp Group To Get Premium Job Alerts-Click Here

Top 10 Interview Questions at Jindal Steel Ltd

Here are the most commonly asked interview questions at Jindal Steel Ltd, along with answers to help you prepare:

-

What do you know about Jindal Steel Ltd?

Jindal Steel Ltd is one of India’s largest steel manufacturers known for innovation, sustainability, and quality. -

Why do you want to work here?

I admire Jindal Steel’s commitment to excellence and its reputation for employee growth and development. -

Can you describe your previous experience in the steel industry?

My experience includes [specific examples] of handling projects in production/quality assurance/costing. -

How do you handle tight deadlines?

I prioritize tasks, delegate where necessary, and maintain clear communication to ensure timely delivery. -

What are your strengths?

My strengths include leadership, analytical thinking, and problem-solving skills. -

How do you ensure compliance with industry standards?

I stay updated on regulatory changes and implement best practices through regular audits and training. -

What steps do you take to improve processes?

I analyze performance metrics, identify inefficiencies, and recommend actionable improvements. -

Can you work under pressure?

Yes, I excel under pressure by staying focused, organized, and maintaining a calm demeanor. -

What motivates you?

I’m motivated by challenges and the opportunity to contribute to organizational success. -

Where do you see yourself in 5 years?

I see myself growing within Jindal Steel, contributing to larger projects, and taking on more responsibilities.

Conclusion

The latest career opportunities at Jindal Steel Ltd-2025 offer a platform to grow and thrive in the steel industry. With a variety of roles across locations, Jindal Steel provides a dynamic and rewarding work environment. Take the next step in your career and apply today!

Keywords: Latest Career Opportunities at Jindal Steel Ltd-2025, Jindal Steel jobs, steel industry careers, Jindal Steel Ltd openings.

Apply Now

- NCR Voyix Amazing Job Opportunities – 2025

- FLSmidth Exciting Job Opportunities in Chennai

- Bajaj Auto Explore Top Job Openings – 2025

- Ashok Leyland Exciting Job Opportunities – 2025

- Exciting Job Opportunities at Tesla

- Reliance Jio Exciting Job Opportunities – 2025

- Graduate Trainee Job Opportunities at Vedanta

- Exciting Job Opportunities at KONE-2025

- Latest Top 20 Job Openings at Adani – 2025